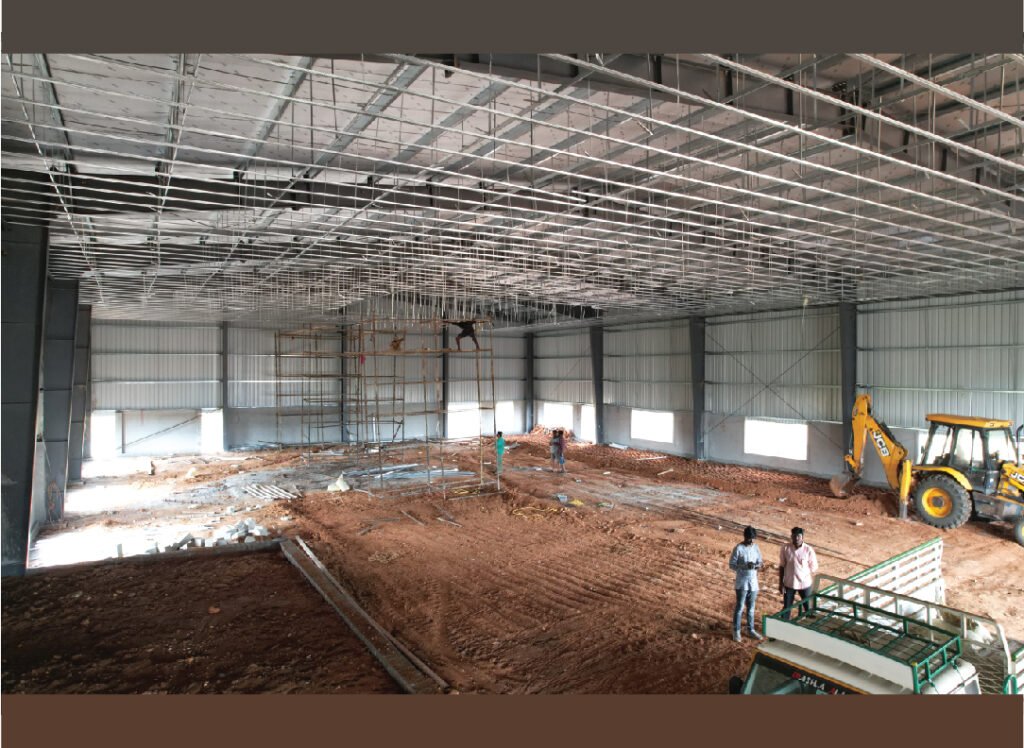

Pre Engineered Building

The Pre Engineered Building is a metal enclosure building that includes a structural frame and standard roof and wall support which is factory made and is erected at the site. Pre-Engineered Building is a new manufacturing concept replacing traditional manufacturing. PEBs is seen as a breakthrough in the construction industry, resulting in less construction time, cost-effectiveness, high quality, low maintenance, consistent span. Pre-engineered buildings meet one of industry’s most critical criteria that is wide, column-free areas.

There has been a substantial rise in Pre Engineered buildings in recent years. Due to rapid construction developments and an increase in the need for quick-track construction in India.

In addition to being economically efficient, pre-engineered buildings are environmentally friendly ways to counter global warming. The prefabricated building saves time because it is designed in a very short period. The parts are prefabricated in accordance with the specification and transported to the site where they are assembled.

Usually, PEBs are steel structures. Developed segments are manufactured at the factory to correct size. There are two types of systems associated with Pre Engineered Buildings – primary and secondary.

Know About Pre Engineered Buildings:

Primary Member:

Primary framing of a PEB is an arrangement of built-up I-shaped steel members & framing consisting of trusses or castellated beams etc. all structural elements that pass the load to the base and consist of End wall frames. End walls are either designed with economical bearing frames or with rigid frames. Such frames are reinforced with wind bracing, connecting bolts, if necessary anchor bolts. Instead of individual parts, a combination of these three components and weather covering sheeting results in robust steel constructions. In traditional structures, separately built and stand-alone frames are individual columns and trusses that result in a large, heavy structure.

Secondary Member:

The secondary structure consists of roof purlins, wall girts, struts, and clips, etc. which help and support the primary framing of roof and wall panelling. The secondary framing method consists mainly of Z and C purlin types of various sizes. The first method contains rafters and columns, while C and Z Purlin have been involved in the preservation of the structure. In contrast with traditional beams, channels and angles the application of purlins help to reduce costs. For the overall stability of the building structure, Purlin / Girts transfers force and instants from one frame to another and functions as a framing device for weather covering sheeting needs. Purlins are available in various lengths and thicknesses, ensuring no cost of production and wastage. Purlins can be easily mounted, resistant to corrosion, lightweight and robust.

Roof and Wall Panels:

With this group typically comes tin shades & curtain wall crafted from glass & rolled steel sheets. For the transfer of wind force and other acting loads, the frame to the foundation is used to convert the trajectory of forces in order to reduce the effect of the forces.

There are also other options, such as special roofing sheets, that will help minimize energy usage, in particular in colder regions. It is no surprise that PEBs are the future of construction and manufacturing worldwide with benefits like less construction time, lower the cost of materials and function, increased energy quality and sustainability through modular design.

PEBs once done with primary and secondary members and enclosed with Roof and wall panels need some accessories to make it waterproof, weather proof, and have a good working environment inside the building. Self-Driven Roof Top Ventilator, Skylight Sheets, Flashings, Insulations, Cage ladder, Mezzanine Floor, Cranes, Cable Trays, Ducts, Hooks to hang Lights and many more can be added to PEBs as per requirement.

If you are interested in Pre Engineering Buildings, Please call us at 9626234599 or drop us a mail at infinitestructurepvtltd@gmail.com for more details.

For Booking

+91 9626234599

infinitestructurepvtltd@gmail.com

Follow Us Our Social Media